Extended projects 2013 cohort

- Non-collinear methods for nonlinear ultrasonic detection of fatigue in aluminium & weak bond-lines in composites

- The development of embedded vascular networks in FRP as active/passive thermal management tools for cure processing

- Hierarchical complex fibrous architecture for additive layer manufacturing

- A comparative study of analytical and cohesive-based laminate failure mechanisms dominated by free-edge delamination

- Crash simulation of tufted sandwich components for automotive applications

- Low cost gamified training for composite layup: a feasibility study

- Understanding the deployment of paper architectures in water for developing smart materials with programmable actuations

- Advanced aeroelastic tailoring of composite wind turbine blades

- Effects of layup and misalignment in a post-tensioned glass fibre-reinforced polymer modular bridge

- Micro-scale modelling of fibre volume fraction effects on transverse mechanical properties in composite materials

- Investigating the feasibility of through-thickness tufting with discontinuous carbon fibre scraps

- A novel fibre placement technology for high-volume production of complex composite parts: continuous multi tow shearing

Non-collinear methods for nonlinear ultrasonic detection of fatigue in aluminium & weak bond-lines in composites

Student: Jonathan Alston

Student: Jonathan Alston

Supervisors: Anthony Croxford, Ian Bond, Jeff Sargent (BAE Systems, ATC) and Amir Rezai (BAE Systems, ATC)

Inspection of bond-lines between composite parts is currently a difficult/impossible process. Present methods are not very sensitive to weaknesses in the bond, due to the apparent continuity of the material despite its lack of strength. The aim of this project was to explore the use of a nonlinear ultrasound technique to detect weakened bond-lines. It is known that kissing bonds in particular exhibit non-linear behaviour due to the interaction of the two faces being pressed together. A non-collinear approach was used to filter out the nonlinearities of the rest of the experimental system. Initial testing was conducted on aluminium samples since the behaviour of ultrasound inside them is simpler. In the case of aluminium the fatigue state was investigated since it is linked with the increase of the third order elastic coefficients of the material. Progress was made in the development of the non-collinear method, building up ‘finger prints’ of a material’s nonlinear response to a range of input ultrasonic waves. The idea is that regions of these finger prints will show sensitivity to fatigue in the case of aluminium, or weakened bond-lines in composite assemblies.

The development of embedded vascular networks in FRP as active/passive thermal management tools for cure processing

Student: Giampaolo Ariu

Student: Giampaolo Ariu

Supervisors: Ian Bond, Richard Trask, Andrew Lawrie and Adam Bishop (Rolls-Royce)

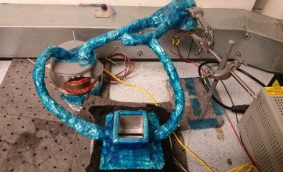

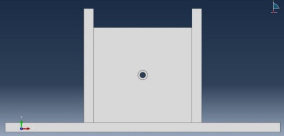

The feasibility of the principle of embedding vascular networks in thick composite laminates for the optimisation of the curing process was investigated. This was carried out through the use of relatively high temperature mediums such as silicone oil through a network of vascular tubes as a cure system. The purpose is the homogenisation of the temperature level through the laminate thickness and the control of the exothermic reaction and the cure cycle. A lab-scale demonstrator was manufactured as proof-of-concept setup, and the heat transfer phenomena were investigated within a viscous fluid (i.e. silicone oil). Finite element analysis

The feasibility of the principle of embedding vascular networks in thick composite laminates for the optimisation of the curing process was investigated. This was carried out through the use of relatively high temperature mediums such as silicone oil through a network of vascular tubes as a cure system. The purpose is the homogenisation of the temperature level through the laminate thickness and the control of the exothermic reaction and the cure cycle. A lab-scale demonstrator was manufactured as proof-of-concept setup, and the heat transfer phenomena were investigated within a viscous fluid (i.e. silicone oil). Finite element analysis of the heat transfer phenomenon within a viscous medium and the cure process in a randomly oriented composite part was carried out in Abaqus, by replicating the experimental setup. It is proposed that cure processing can be carried out within the composite part thanks to the internal heat sources from the network and exothermic reaction. This can lead to the optimisation of the cure approach for more complex composite structures, or those of significant size.

of the heat transfer phenomenon within a viscous medium and the cure process in a randomly oriented composite part was carried out in Abaqus, by replicating the experimental setup. It is proposed that cure processing can be carried out within the composite part thanks to the internal heat sources from the network and exothermic reaction. This can lead to the optimisation of the cure approach for more complex composite structures, or those of significant size.

Image top right: Experimental setup. Image bottom right: Abaqus modelling representation.

Hierarchical complex fibrous architecture for additive layer manufacturing

Student: Laura Beckett

Student: Laura Beckett

Supervisors: Wuge Briscoe and Richard Trask

Hierarchical fibre architectures are desirable in order to try and apply successful failure mechanisms found in nature to man-made composites. In a previous XP project on this topic it was demonstrated that zinc oxide (ZnO) nanorods could be grown radially from glass fibres under mild reaction conditions without causing degradation of the fibre tensile strength. The two-step method involved first ‘seeding’ the fibre with ZnO crystallites before carrying out a growth reaction to obtain the desired nanorods.

The purpose of this project was to continue to investigate the growth process, in particular to demonstrate control over the nanorod morphology in order to obtain fibres with tuneable interfacial properties. By altering reaction conditions such as the number of seeding steps and growth time it was possible to vary the nanorod density, diameter and length. It has been shown in planar systems that the addition of a structure directing agent during a secondary growth step promotes branched growth from the primary ZnO array, and so work was carried out to further modify the fibre to obtain novel, branched surface structures.

A comparative study of analytical and cohesive-based laminate failure mechanisms dominated by free-edge delamination

Student: Bradley Cox

Student: Bradley Cox

Supervisors: Michael Wisnom and Stephen Hallett

Delamination is a critical failure mechanism in laminated fibre-reinforced polymer matrix composites, and is one of the key factors differentiating their behaviour from that of metallic structures. There currently exists an extensive array of research undertaken on delamination owing to through thickness stresses, however it is less widely appreciated that delamination has a crucial role on the in-plane strength of a laminate, frequently leading to premature initiation of failure. This in-plane failure of composite structures is driven by the energy released as fibres are unloaded. This energy is released in primarily two methods, (i) by the fracture of fibres, and (ii) by the delamination and matric cracks joining up to produce a fracture surface without the need to break fibres.

During failure, composites will find the lowest energy route to shedding load, and sometimes this occurs by delamination and splitting rather than fibre fracture.

Classical Laminate Plate Theory (CLPT) was used to determine a theoretical tensile strength of a quasi-isotropic laminate, [45m, 90m, - 45 m, 0m]ns, of IM7/8552 to be 1077MPa. However, experimentally, it was shown that this strength is never achieved. A comparison of both dispersed-plies (n = 1, 2, 4) and blocked-ply laminates (m = 2, 4, 8) was carried out and illustrated a significant reduction in failure strength, blocked-ply laminates of m = 2, 4 and 8 plies per block were used, respectively resulting in average failure strengths of 660, 458, and 321MPa. This shows a characteristic reduction in strength directly proportional to laminate thickness, however when the dispersed-ply laminates were tested the reverse was observed where failure strength increased with laminate thickness.

This was due to the delamination at the free-edge, this energy release was greater for laminates with thicker delaminating plies, i.e. the ply-blocks.

In order to better understand the mechanisms involved extensive high-fidelity modelling has been carried out using cohesive elements at the interface of each ply. The results are then compared directly to the available closed form analytical and numerical solutions currently available - a good correlation was observed.

Further analysis was carried out in order to delay the onset of free-edge delamination by moving a single 90⁰ ply closer to the surface immediately underneath the first 45⁰ ply. This was shown experimentally and numerically to delay the onset and propagation of delamination.

Crash simulation of tufted sandwich components for automotive applications

Student: Jamie Hartley

Student: Jamie Hartley

Supervisors: Carwyn Ward, James Kratz, Ivana Partridge and Dirk Lukaszewicz (BMW)

The future of the automotive industry is likely to feature a significant increase in the use of composite materials to meet weight reduction requirements. Lightweight composite sandwich structures have the capability to satisfy this requirement as well as serve as good energy absorbing components in crash situations. However, buckling or disbonding of the face skins during side-on impact can lead to a substantial reduction in performance. Through-thickness reinforcement (TTR) in the form of tufting has been shown previously to result in significant improvements in the energy absorption of these sandwich structures, but work in the area is still limited with little understanding of how the TTR behaves or the way the design parameters and manufacturing process can affect performance.

This research focused on developing a finite element model based at the unit-cell level in LS-DYNA to investigate the behaviour of an individual tuft. A number of highly novel small scale specimens were also created, based around individual tufts with varying input parameters and tested in static compression. These were used to explore the effect of changing the tufting parameters as well as being used to validate modelling results.

Low cost gamified training for composite layup: a feasibility study

Student: Shashitha Kularatna

Student: Shashitha Kularatna

Supervisors: Carwyn Ward, Kevin Potter, Pablo Bermell-Garcia (Airbus Group Innovations) and Richard Middleton (Airbus Group Innovations)

Hand layup is still the dominant forming process in the manufacture of complex composite parts. But, this process is still poorly understood and delivery of training to hand laminators is yet to be standardized. Aligned to this is a shortage of hand laminators with the necessary skills with countries such as the UK aiming to double its composite workforce by the year 2015.

In trying to address some of these issues, a feasibility study was carried out through this project on the use of a relatively low cost and readily accessible virtual reality (VR) system as a platform to deliver standardized training to amateur laminators. A VR training aid for composite layup, based in a clean room environment was designed using the Unity 3D gaming engine and delivered to users via a head mounted, smartphone based system with a handheld game controller as the input medium. The training aid guides the user through a series of composite manufacturing steps in a virtual environment, from entering the room, procedural requirements, process of documentation and layup tasks, through to completing a demonstration panel.

Results from the post analysis of the training aid suggested a significant shortening of the learning curve of amateur laminators, implying such technology can play a major role in addressing certain skills and training issues that exist in the composites industry.

Understanding the deployment of paper architectures in water for developing smart materials with programmable actuations

Student: Manu Mulakkal

Student: Manu Mulakkal

Supervisors: Richard Trask, Ian Manners and Annela Seddon

The purpose of the work carried out was to achieve a scientific understanding of the deployment of folded origami paper architectures in water and to use this knowledge in developing smart material systems for engineering applications. The physical and chemical properties, and mechanisms of different paper types were characterised by a series of experiments investigating the influence of porosity, moisture, surface energy, surfactant concentration, temperature, water retention and hornification, during the folded origami moisture driven deployment. As expected, the results showed the clear role of hydration and interaction of hydrogen bonds within the fibrous architecture driving the deployment of the folded region. The work also examines concepts to reverse and or control the deployment by modifying the actuation environment and the cellulosic paper fibres itself, to make a truly reversible deployment architecture. Paper samples grafted with a thermo-responsive polymer was found to resist full deployment (stopping at 90⁰) above its lower critical solution temperature (LCST). This opened up a potential avenue for exploring reversible deployment.

Advanced aeroelastic tailoring of composite wind turbine blades

Student: Muhammad Othman

Student: Muhammad Othman

Supervisors: Alberto Pirrera, Paul Weaver, Xavier Lachenal and Graeme McCann (DNV GL)

In recent years, the global demands for the renewable energy continued to increase due to reduction in the cost of energy and emerging new technologies. Wind power in particular, accounted for about 39 % of global renewable power capacity added in 2012 and about 9 % contribution to the UK power needs in 2013. The steady growth and increasing demand on wind power has led to development of larger wind turbine rotor that produces more energy and cost efficient. Having said that, the demand of mass efficient turbine blade is become more evident where higher energy output can be harvested while keeping the costs at minimum.

In this work, an advanced aeroelastic approach is adapted to introduce a blade concept of optimum twist response for improved energy yield potential and load alleviation on larger wind turbine blade. A 5 MW turbine blade (61.5 m) from National Renewable Energy Laboratory (NREL) is used as the baseline blade. Aerodynamic analysis aimed at optimising the turbine`s power performance was performed to identify the ideal aeroelastic behaviour of the blade. By tailoring the materials and structural bend-twist couplings, elastically-induced twists were introduced accordingly on the blade structure while bending towards feather. The responses of new wind turbine blade design in term of load alleviation and Annual Energy Potential (AEP) subjected to stochastic wind field conditions are studied. The potential of pitch less blade design concept was also investigated. The analysis are performed using in-house Matlab code and commercially available software Bladed. The results show that by tailoring the blade`s elastic response to aerodynamic pressure, the AEP`s values are increased and load reductions due to gust are achieved.

Effects of layup and misalignment in a post-tensioned glass fibre-reinforced polymer modular bridge

Student: Jakub Rycerz

Student: Jakub Rycerz

Supervisors: Alberto Pirrera, Paul Weaver, Roland Trim (Arup), Natalie Price (Arup) and Ian Wise (Arup)

Interface analysis of a modular GFRP footbridge concept inspired by prestressed concrete construction is presented. Structural analysis of the bridge is demonstrated. Material properties of trial manufacturing elements are characterised. Finite element analysis is performed to quantify the interfacial response under load. Layup and misalignment variation effects are investigated. The results have shown that wrapping the fibres around the interface helps in dissipation of stress concentrations. The presence of resin not only does not prevent stress concentrations, but can create them.

Micro-scale modelling of fibre volume fraction effects on transverse mechanical properties in composite materials

Student: Emily Withers

Student: Emily Withers

Supervisors: Stephen Hallett, Jonathan Belnoue and Xiangqian Li

Modelling of fibre-reinforced composites at the macro-scale requires an understanding of the micro-mechanical behaviour including their complex failure modes. The volume fraction (Vf) at local level will affect the macroscopic properties and though composites are designed assuming average Vf whereas in reality the Vf may vary significantly, sometimes up to 80%. Little work has been done to model these areas of high fibre content because of the difficulty in manufacturing and testing such samples.

With the aim of understanding how these regions affect transverse mechanical properties this investigation looked to create a method to predict these properties using representative volume elements (RVE). Numerical models were created in LS-DYNA by first using an algorithm to generate the random distribution of the fibres within the RVE but with periodicity at the boundaries. Periodic boundary conditions were applied to mimic the effect that surrounding material would have under load. The developed method resulted in models that match the behaviour observed in experimental analyses, and further work in this area will contribute to the accuracy of composite modelling.

Investigating the feasibility of through-thickness tufting with discontinuous carbon fibre scraps

Student: Xun Wu

Student: Xun Wu

Supervisors: Carwyn Ward, James Kratz, Ivana Partridge and Dirk Lukaszewicz (BMW)

Some of the technological issues the automotive industry faces in the short term are those of increasing the use of lightweight structures, further developing fuel economy, and ensuring passenger safety requirements. To achieve this, some companies are beginning to explore advanced composites as a viable alternative to metallic structures, as it potentially offers high energy absorption with mass reductions for equivalent sized components. That said the manufacture of components with relatively standard advanced composite forms leads to a high material waste and so scrap burden. Presently some manufacturers employ the scrap in non-load-bearing components and largely in a random format. The reuse of scrap in this manner is not optimised, and previous works have shown that when aligning the scrap, high performance is possible. Such alignment and optimisation in a layup pattern is however costly and prohibitively slow, thus methods to keep the performance while reducing the manufacturing burden is required. One possible method towards this goal could be the incorporation of through thickness reinforcement in the structure - where scrap layup can be simplified for overlaps etc. by employing tufting about the discontinuities. This study explored the incorporation of these technologies, in order to obtain advanced composite structures with optimised manufacturing, and through thickness properties with improved energy absorption performance. It found that an idealised combination of discontinuous scraps and tufting can improve energy absorption relative to untufted forms for simplified layup configurations, however, overall performance was compromised in comparison to highly aligned and organised layup’s and continuous materials.

A novel fibre placement technology for high-volume production of complex composite parts: continuous multi tow shearing

Student: Evangelos Zympeloudis

Student: Evangelos Zympeloudis

Supervisors: Kevin Potter and Byung-Chul Kim

Automation is a highly desired property in composites manufacturing and especially in the aerospace industry. The demands of the industry however exceed the capabilities of the most commonly employed material placement machines. In particular, as the application of the fibre placement technologies expanded to more complex parts, tow steering became one of the most critical capabilities. Since the steering process causes many different types of defects, their minimization became a major issue nowadays. The concept of Continuous Multi Tow Shearing (CMTS) addresses these issues by shearing the tows, during the placement process, instead of inducing in-plane bending. Its superb steering capability in conjunction with high material deposition rates will allow CMTS to obtain a niche position in the field of automated composites manufacturing. During this project a complete experimental simulator of the CMTS process was developed, comprising of a CNC Cartesian bed and a novel material placement head. Furthermore, the methodology that will allow benchmarking and further development of the CMTS was formulated.