Thermal Management Wind Tunnel

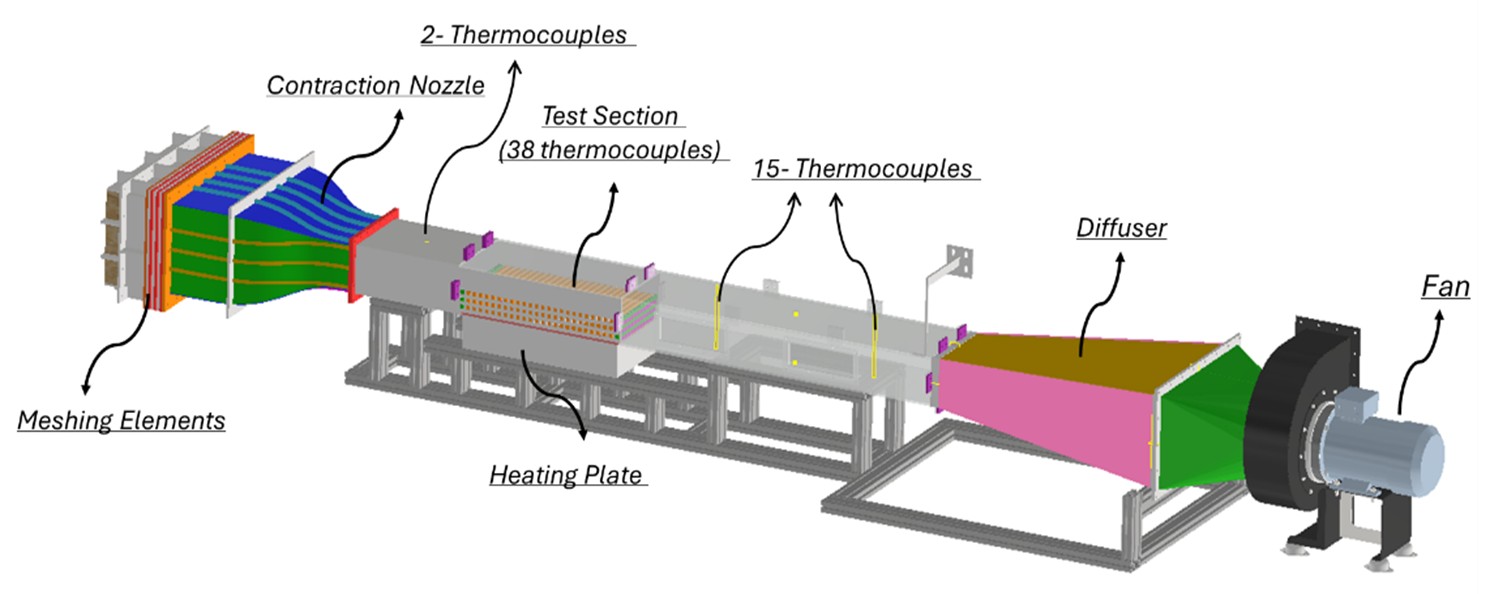

The thermal management wind tunnel at the University of Bristol is a horizontal, rectangular flow facility designed for controlled thermal and aerodynamic testing. Constructed entirely from transparent polycarbonate, the tunnel offers full optical access while minimising heat loss, making it particularly well-suited for flow visualisation and quantitative measurement. The test section measures 289 mm (width) × 612 mm (length) × 153 mm (height), with an additional 1200 mm downstream extension maintaining the same cross-section. This section is instrumented with thermocouples for monitoring temperature distribution and includes access ports for hot-wire and an infrared thermal camera, enabling detailed characterisation of velocity, temperature, and turbulence statistics.

Airflow entering the test section is conditioned using a contraction nozzle equipped with honeycomb and mesh flow straighteners, which reduce turbulence intensity and promote a uniform velocity profile. At the outlet, a diffuser gradually expands the flow, aiding in pressure recovery and minimising exit velocity losses. A variable-speed axial fan, mounted at the downstream end, draws air through the system to ensure steady and adjustable flow conditions. The tunnel supports airflow velocities ranging from 0.2 m/s to 8 m/s and can operate with heated air up to 100 °C, supporting a wide range of heat transfer experiments.

Thermal input to the system is provided by a custom industrial hot plate, featuring a mild steel top surface measuring 305 mm × 610 mm × 8 mm. The plate is heated via mineral-insulated, metal-sheathed heating elements arranged beneath the surface to ensure uniform temperature distribution. The system includes an integrated 0–300 °C thermostat and is powered by a 230 V, 50 Hz, single-phase supply, delivering a total heating capacity of 2.5 kW. The hot plate is encased in a stainless-steel housing, ensuring both durability and corrosion resistance.

Together, the wind tunnel and integrated heating system provide a flexible and precise platform for investigating thermal-fluid interactions, making it a valuable asset for experimental research in fluid mechanics and heat transfer.