A new high pressure high temperature (HPHT) rheometer for measuring the viscosity of volatile-bearing magmas

Haywood F, Brooker R, Mader H, Breeze L, Clapham C, Lindoo A, Mwale G

Magma rheology exerts a primary control on a wide range of volcanic processes, from the extraction of magma from the deep earth, during its transport towards the surface, and finally its extrusion at earth’s surface, either as a gentle effusive flow or a violent explosive eruption. Throughout this journey, magma experiences significant changes in pressure and temperature, as well as crystal and volatile content that affect the bulk rheology. It is clear that reliable measurements of the viscosity of volatile-bearing magmas at these high pressures and temperatures are needed to constrain models that predict transport and particularly, eruptive behaviour. However, current viscosity measurements of high temperature materials are often limited to anhydrous, ambient pressure conditions as a consequence of the difficulty posed in adding a pressurised chamber to a standard rheometer.

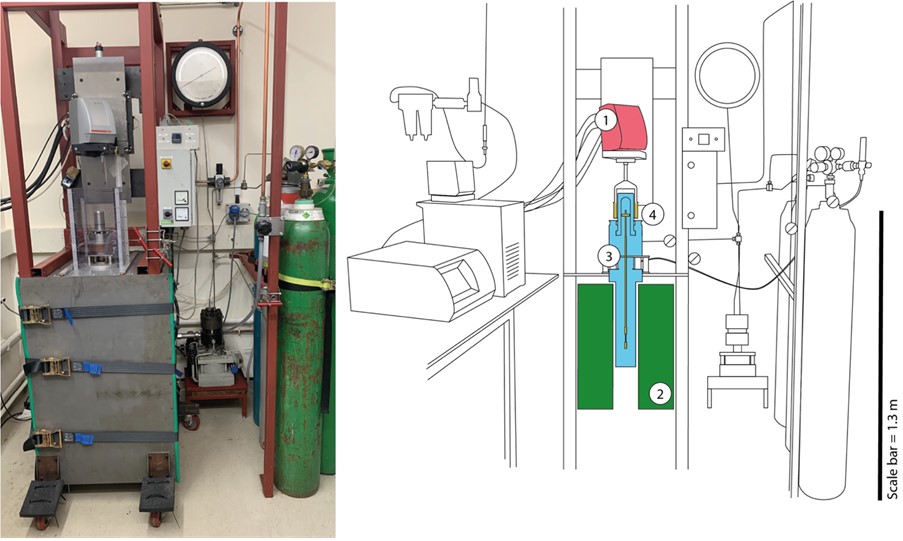

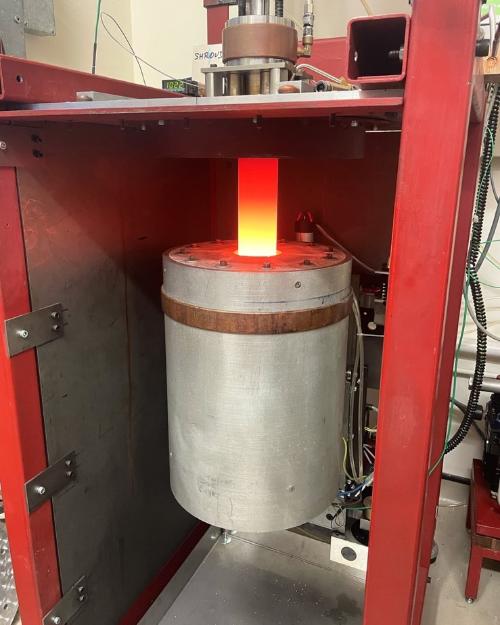

The petrology group at Bristol have developed the first HPHT concentric cylinder rheometer capable of measuring magmas over the range of conditions experienced during volcanic eruptions. Our new apparatus (Fig. 1) combines a cold seal-style pressure vessel (Fig. 2) with a classic concentric cylinder rheometer configuration via a magnetic coupling which links an external rheometer motor without compromising the sealed pressure vessel. The rheometer is currently capable of achieving pressures and temperatures up to 250 MPa and 1120°C and measuring viscosities in the range 100 Pa s - 30,000 Pa s. An exciting feature of this machine is the ability to also record dynamic pressure-temperature conditions with a single experimental set up.

This newly developed apparatus will soon offer the first access to rheology measurements on a range of different magmatic compositions at the pressures required to maintain high volatile contents.

Figure 1: The key features of our HPHT rheometer apparatus. (1) Anton Paar dynamic shear rheometer, (2) SiC vertical tube furnace, (3) pressure cell and (4) magnetically coupled measuring system

Figure 2: The pressure vessel being heated by the surrounding vertical furnace.

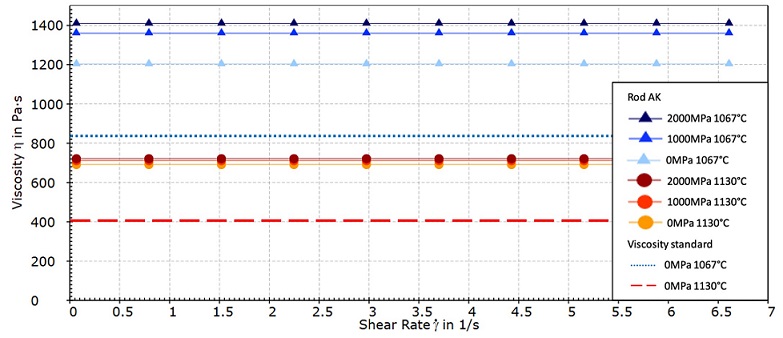

Figure 3: One of our first runs using a viscosity standard. The difference between the standard and the measured value at 0MPa is due to frictional losses that can be corrected for. The system clearly resolves viscosity changes as a function of P and T.