Optical tweezers are systems that use laser beams to ‘trap’ and manipulate very small particles. They have been around for some years and are used to investigate numerous areas within physics, chemistry and biology, but they are highly optimised for specific tasks and seldom allow the control of more than one trap at a time, thus proving to be rather limited in their function. Around 2002 a new technology emerged – a computer-controlled hologram – which suddenly allowed scientists to control more than one focused laser beam at a time, and therefore move more particles.

A hundred laser beams can be precisely focused and individually manipulated in full 3D

But, like much of today’s technology, within a short time even this improved facility was not sufficient for Carberry and his colleagues in the bio- and nanoscience groups who wanted to use such holograms to control dozens of particles at a time. So, in collaboration with colleagues in Glasgow, they built the Dynamic Holographic Assembler (DHA). This state-of-the-art machine now allows users to simply click on a screen and use the mouse to position a laser beam exactly where it is needed in order to ‘trap’ the required particle, which can then be moved into position. Furthermore, a hundred beams can be focused in this manner, and they can each be manipulated individually in full 3D. But despite this improvement, the team considered the system was still not ‘friendly’ enough for non-specialist use, so its next goal was to design a very intuitive interface that even a child could use.

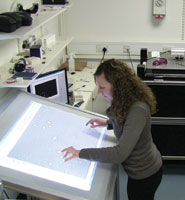

In collaboration with the University’s Department of Computer Science, a multi-touch table was developed that would allow each of these optical traps to be controlled by using one’s fingers. The multi-touch table looks very much like a large PC monitor lying face up on a table. On it a few dozen round particles, roughly the size of a marble, are randomly displayed. These particles are actually beads of silica about two microns in diameter – three times smaller than a red blood cell – that are lying under the microscope positioned on top of the DHA. They have been greatly magnified and projected on to the multi-touch screen. To demonstrate how they can be moved, Carberry places three of his fingers on the images of three silica beads and, pressing very gently, he drags them across the screen, lining them up in a neat row. Further beads are captured to form new rows and then another layer is built on top of the first one. Gradually it becomes apparent that he is forming a 3D structure which, in reality, is being built under the microscope across the other side of the room.

The dynamic holographic assembler could become one of the manufacturing processes of the future, turning out photonic crystals instead of microchips

Ultimately, what Carberry wants to be able to do is assemble a much larger 3D structure called a photonic band gap crystal. Photonic crystals are structures with deliberate defects and impurities, and with properties that prevent the propagation of certain frequencies of light, while permitting others. Such properties will enable Carberry to control light with amazing facility and produce effects that are impossible with conventional optics. In the same way that transistors enabled all the micro-electronics of today, photonic crystals will act as a ‘switch’ for photons (light) and enable tomorrow’s optical computers. The DHA could therefore become one of the manufacturing processes of the future, turning out photonic crystals instead of microchips. But that’s only one aspect of what the group is doing. Another is building nanotools, which in turn will enable the team to build nanostructures to build even smaller nanotools, with which to build even smaller nanostructures until eventually individual atoms can be controlled. Carberry demonstrates one part of this process by attaching two beads together using a tiny nanorod.

He then shows how, using the two beads as handles, he can move the tool around. Being able to do this efficiently will enable the micro-manipulation of things such as brain cells or DNA in order to understand better how they respond to the forces applied to them when, for example, the need to insert or attach a drug arises. Using this nanotool, Carberry can ‘feel’ the force being applied and know how hard to push in order to position a drug very precisely. Alternatively, he may want to determine whether the cell being examined is cancerous. A cancerous cell has very different properties from a healthy cell and, by poking it, more information about its surface properties could be obtained, aiding those engaged in the fight against cancer. These tools may also be capable of modifying cells using a kind of nanosurgery. Collaborations are already under way with biomedical groups working on cardiac stem cells and neurons.

The team has recently won a grant of over a million pounds to push forward this new and exciting technology of the future – a future that, it seems, is not only very bright, but also very small.