Diamonds are crystals of pure carbon that have been subjected to tremendous heat and pressure, deep within the Earth. Each carbon atom is linked to four equidistant neighbours throughout the crystal, making it the hardest naturally occurring substance known. The close-knit, dense, strongly bonded structure yields properties that greatly differ from those of graphite, native carbon's other form. Graphite has a layered structure consisting of rings of six carbon atoms arranged in widely spaced horizontal sheets that easily slide over each other, making it relatively soft. A typical use of graphite is in pencils.

The word ‘diamond’ comes from the Greek adamas, which means ‘unconquerable’

By most measures, diamond is 'the biggest and best'. It has the lowest coefficient of thermal expansion, is chemically inert and wear resistant, offers low friction, has high thermal conductivity, is electrically insulating and optically transparent throughout a very wide wavelength range, stretching from the ultraviolet to the far infrared. Given these remarkable properties, it should come as no surprise to learn that diamonds are already used in many diverse applications such as abrasives and wear-resistant coatings for cutting tools.

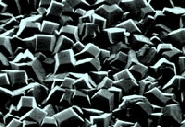

Industrial diamonds have been synthesized commercially for over 40 years using high-pressure / high-temperature (HPHT) techniques in which diamond is crystallised from graphite, using conditions similar to those which create natural diamonds within the Earth. More recently, world interest in diamonds has been increased by the discovery that it is possible to produce polycrystalline diamond films, or coatings, by a wide variety of chemical vapour deposition (CVD) techniques.

Chemical vapour deposition, as its name implies, involves a gas-phase chemical reaction occurring above a solid surface, which causes deposition onto that surface. The gas mixture used in this technique is nothing more exotic than a gas that contains carbon (typically methane) in an excess of hydrogen atoms. The latter are generated as a result of the gas mixture being 'activated', either thermally or via electron bombardment. The activated gas molecules and hydrogen atoms then settle on a surface where the carbon atoms lock together to form a thin diamond coating. The coatings that result can range in thickness from nanometres to millimetres, depending upon which deposition process is used and for how long the deposition apparatus is run.

Chemists in the Diamond Group at Bristol University have been studying the mechanisms of CVD diamond growth for over ten years. Research began with a collaboration between Chemistry and Aerospace Engineering, when the DTI funded a project to investigate diamond films for aerospace applications. This has expanded rapidly, and now the Diamond Group is one of the largest CVD diamond research groups in the UK. Their laboratory contains in excess of £1m worth of equipment that is used to deposit and characterise a range of diamond film types. Their research spans both the fundamental aspects of diamond growth, as well as the possible applications of these coatings.

On the fundamental side, problems such as why diamonds grow under some conditions and not others, and why certain gas mixtures lead to diamond films of very different quality, are investigated. This requires the use of very sensitive analytical techniques – molecular beam mass spectrometry and a range of laser spectroscopies – to sample the gas chemistry. The use of such techniques for diagnosing diamond CVD has been pioneered by the Bristol Diamond Group. The studies are now yielding a wealth of insight that is aiding understanding of the intricacies of diamond growth chemistry.

The possibility of being able to coat large surface areas with a continuous film of diamond will open up many potential applications for the CVD methods. For example, the production of semiconducting diamond films that could be used in electronic devices, computer chips, or flat panel displays, is proving to be of great interest. In an effort to reliably control the conductivity of the diamond coating, while still maintaining its excellent thermal and mechanical properties, a range of novel gas chemistries involving higher than normal methane/hydrogen mixing ratios, as well as the addition of trace amounts of impurities like boron, nitrogen, phosphorus or sulfur to the more traditional gas mixtures, is being explored.

The Bristol group is also noted for its unique capability to produce diamond-coated wires and fibres, which are typically about 10 cm long and have a diameter similar to that of a human hair. These could be used as reinforcing agents in metals and plastics, in much the same way as carbon fibres are used today. The resulting ‘diamond-fibre reinforced composites’ are stiffer and stronger than existing materials, yet are still extremely lightweight, and might therefore find application in aerospace materials, sports cars, or even tennis rackets.

CVD diamond can exhibit mechanical and electronic properties comparable to those of natural diamond. There is currently much optimism that it will prove possible to scale CVD methods to the extent that they will provide an economically viable alternative to the traditional HPHT methods for producing diamond abrasives and heat spreaders.