The smallest bacteria are around 200 nanometres in length; a DNA double helix has a diameter of around two nanometres; and the space between two carbon atoms is only 0.15 nanometres. To put these numbers in context, one nanometre is one billionth of a metre, or the size of a marble when a metre represents the size of the Earth. In other words, incredibly small. With nanotechnology becoming increasingly important in a whole range of scientific fields, being able to see things at higher and higher magnifications is crucial.

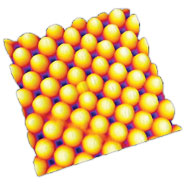

There are several ways of looking at materials at the atomic and molecular scale but many, such as scanning electron microscopes, only work in high-vacuum chambers. This can be cumbersome when loading and unloading samples, which also need to be electrically conductive. A different approach is atomic force microscopy (AFM), although the term ‘microscopy’ is something of a misnomer, because this microscope does not really ‘see’ anything. Information is actually gathered by ‘feeling’ the surface of a sample with a probe, much like the needle of a record player moves over the surface of a record. The advantage of AFM is that the sample does not need to be in a vacuum, so live biological material can be examined. Consequently, AFM has been widely used over the past 20 years to move atoms around and even spell out words using individual atoms, but there are still two major drawbacks: the technique is very slow and it cannot be used for very delicate samples, because it damages them in the process.

The advantage of atomic force microscopy is that the sample does not need to be in a vacuum, so live biological material can be examined

Professor Mervyn Miles, Head of the Nanophysics Group in the Physics Department, and his team took these challenges to heart and resolved to change the way AFM systems were designed, but instead of trying to make the probe smaller, they looked at ways to make the measurements faster by increasing the probe’s sensitivity. Using new combinations of materials with which to build the probe, they first managed to reduce the time it took to generate an image from several minutes to just 50 microseconds, thereby enabling the AFM to produce a series of stills that is, in effect, a video of the sample. A key benefit of this approach is that it allows highly delicate samples to be examined, without destroying them in the process. This sensitivity, combined with the video capability, allows biological samples to be examined as they move and crystals to be watched as they grow, atom by atom, revealing a whole new molecular world.

In 2001, the success of this research led to the launch of a spin-out company called Infinitesima in order to develop novel instrumentation and components for existing AFM systems. Instruments were sold to research groups around the world that are pushing back the boundaries of our understanding of molecular activities and by 2004 the company had moved to its current location in Oxford. In 2006, Infinitesima was selected by Real Business magazine as one of the ‘50 to Watch’ start-up companies in the UK. The selection was recognition of the technology, now called Resonant Probe Microscopy (RPM), that Infinitesima brings to the nanotechnology sector.

VideoAFM delivers real-time video at the molecular level and can be operated much like an optical microscope

Infinitesima now supplies several products based on RPM, including VideoAFM which is capable of observing processes and delivering real-time images at unprecedented rates, enabling large areas of sample to be explored. The microscope probe measures just 100 microns across and is made of silicon or silicon nitride, depending on the type of sample being measured. The instrument delivers real-time video at the molecular level, allowing researchers to operate the apparatus much like an optical microscope, but at staggeringly higher magnifications. A technical advisory board, chaired by Professor Mervyn Miles, is made up of leading scientists and researchers in the field who advise the company on its technological development. Today, Infinitesima has a growing number of staff, including a highly experienced management team, and backing from private investors to take the company forward into new areas.

Silicon wafers, for example, need to be inspected closely and quickly for defects, ideally as part of the production line, but current techniques are too slow and require the wafer to be in a vacuum, which is possible but cumbersome. With high-speed atomic-scale imaging in air, wafers can be examined directly to see whether there are any process defects or tiny particles on it – the equivalent of identifying and taking a picture of a single blade of grass in a football pitch. Another area that has recently opened up is in the processing of semiconductors, where a single atom difference in thickness at certain points can dramatically alter the performance of some devices. Being able to examine atoms directly is therefore of tremendous value.

But rather than video, the semiconductor processing industry needs fast, single pictures which the RPM process is able to provide. RPM is therefore being incorporated into semiconductor processing tools to provide these images on high-throughput, continuous production flows. The first of such products from Infinitesima for this large, established industry was introduced in October 2008.

Beyond the semiconductor market, manufacturing of devices of all types is moving towards the nanoscale. From automotive sensors to mobile phone microphones to digital camera lenses, miniaturisation has progressed to the point where nanoscale inspection techniques are required to ‘see’ what is being produced and Infinitesima is poised to benefit from this rapidly shrinking world.