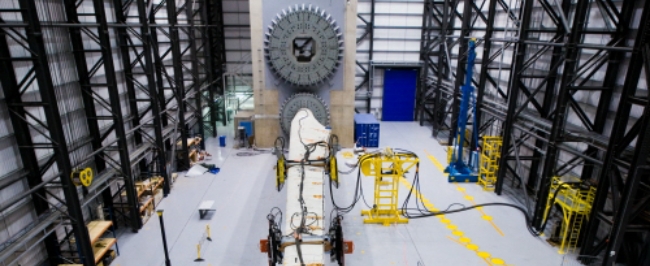

Wind Blade Research Hub

Adaptive structures present a novel solution for wind energy production.

The challenge

The UK is currently committed to fulfilling 15 per cent of all energy from renewables by 2020. Meeting this target, as set by the EU Renewable Energy Directive, will require significant cost reductions, which experts propose can best be achieved with more sophisticated designs, new technologies and cost savings in manufacturing and maintenance.

Currently, offshore wind turbines harness around 8 MW at rated capacity, with components designed to last up to 20 years or more. That capacity will need to be doubled if the UK is to meet its renewable targets.

While innovations and increased competition in the wind energy sector have resulted in lower costs, the drive to build larger and more sophisticated technologies that maintain a high rate of energy production has increased engineering challenges.

What we're doing

Now, thanks to a £2.3m collaborative project involving the University of Bristol and the Offshore Renewable Energy Catapult, experts in aerospace engineering are investigating a potential solution.

Using principles of aeroelastic tailoring, i.e. exploiting the interplay between the material and geometric properties of aerodynamic structures, Bristol researchers have found a way of creating adaptive blades capable of changing shape in response to varying wind conditions, thereby mitigating operational loads and improving energy harvesting characteristics.

These structures are capable of withstanding greater aerodynamic pressures and yield more energy by deforming to maintain the optimum shape for maximum power generation.

How it helps

Dr Alberto Pirrera, Senior Academic Lead with the Wind Blade Research Hub (WBRH), says: “Previous researchers have investigated shape adaptation but in a way that compromised energy production or blade weight and durability. We are the first to find a way around that. With further investment and research, we’d like to ultimately reach the point where we can collaborate with industry to develop these technologies further.”

The WBRH eventually plans to design blades of up to 100 m in length with the capacity to harness 13-15 MW at rated power.

Investigators

- Professor Paul Weaver, Department of Aerospace Engineering, Bristol Composites Institute (ACCIS), Scientific Director of WBRH

- Dr Alberto Pirrera, EPSRC Early Career Research Fellow, Department of Aerospace Engineering, Bristol Composites Institute (ACCIS), Senior Academic of the WBRH

- Paul McKeever, ORE Catapult's Head of Strategic Research.

Lead researcher profile

Lead researcher profile

Paul Weaver, Professor in Lightweight Structures

Related research centres

Partner organisations

- Offshore Renewable Energy Catapult

Funders

- University of Bristol

- Offshore Renewable Energy Catapult

- Innovate UK