Improving environmental remediation

Researchers at the University of Bristol have developed a nano-filter which may help decrease costs associated with the remediation of contaminated sites as well as reduce risks to human health and the environment.

According to the European Groundwater and Contaminated Land Information System, there are anywhere between 300,000 and 1.5 million contaminated sites in Europe with estimated remediation costs exceeding seventeen billion Euros.

Iron particles have been used in remediation for over twenty years, but at the micro and millimetre scale. Contaminants such as uranium sorb onto the metallic iron surfaces and are chemically reduced through the corrosion process, and ultimately immobilized. The cheapest way to improve the efficacy of the iron is to increase the reactive surface area, and the easiest way to do that is to move to the nano-scale.

The use of nano-sized iron in remediation is relatively new, but has proved to be highly effective at removing contaminants at a fraction of the cost of existing remediation technologies. Depending on the site, the cost of using free nano-iron may be 10 per cent of the cost of typical pump and treat technologies. Yet, despite the efficacy of nano-iron, its fate and reactivity once released into the environment is not well understood, which has caused concern regarding the licensing of this technology in many countries, including the UK.

One of the many concerns about nano-particles is that due to their size they are capable of passing through cell membranes and accumulating with potentially toxic effects. Those that handle the free nano-particles are most at risk of exposure.

The nano-composite filter developed by Dr Tom Scott, Director of Bristol's Interface Analysis Centre, and his colleagues, takes advantage of the high reactivity of nano-iron whilst eliminating the potential toxic threats it poses by depositing it onto a substrate.

Previous attempts at creating nano-composites have used grafting methods that can change the nano-particle and therefore alter its reactivity. However, Scott and his colleagues have developed a method that maintains the particle’s reactivity.

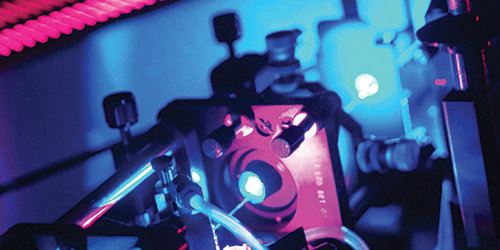

The researchers use an electrochemical method, known as electrodeposition, to coat a sponge-like carbon glass with nano-iron. An electrode is connected to the carbon glass substrate, which is immersed in a solution of a nano-iron suspension and iron salt. When a low current is applied, the nano-iron is co-deposited on the surface of the substrate and cemented down by the iron salts. The result is a one nano-particle thick film of highly reactive iron on the surface of the carbon glass – a nano-filter.

The nano-filters can be used as a permeable reactive barrier in the ground, made into an in-line filter for water, or even placed on the end of a tap, which makes them extremely versatile. Moreover, the filters are essentially reusable.

“Once the filter is reactively exhausted,” said Scott, “you can take it out of the inline filter or out of the ground and put it back into an electrolyte solution, reverse the polarity, and all the metals collected can then be driven off into concentrated solution. Some metals, such as nickel, zinc and chromium, can be worth a lot of money and this helps recover the costs of the remediation scheme.”

The filters have been tested on heavily contaminated groundwater by the environmental company Chemtest. When differences in the surface area of the materials were taken into account, the nano-filters performed one hundred times better than the industry gold standard - granular activated carbon. The Bristol team is continuing work with Chemtest as well as colleagues at the University of Brighton to develop the technology into a full field-scale pilot program. A collaboration that will help transfer the technologies developed at the Interface Analysis Data Centre into the commercial arena.

“It’s a two way relationship,” said Dr Jamie Cutting, Technical and Commercial Manager of the Geochemistry Lab at Chemtest. “It gives us the opportunity to provide cutting edge technologies to our clients, and it helps university researchers transfer these technologies into the commercial world.”

The Bristol researchers are also exploring the utility of generating other nano-composite materials and have successfully produced nano-composites using diamond, silver, gold, platinum, palladium and titanium dioxide. This has resulted in a highly effective anti-bacterial water filter using nano-particles of titanium dioxide, which is also being developed in collaboration with industry partners.

Related research groups

Study Physics

Study Physics

Contribute to cutting edge research at the very frontier of scientific knowledge.