Ultrasonic particle manipulation

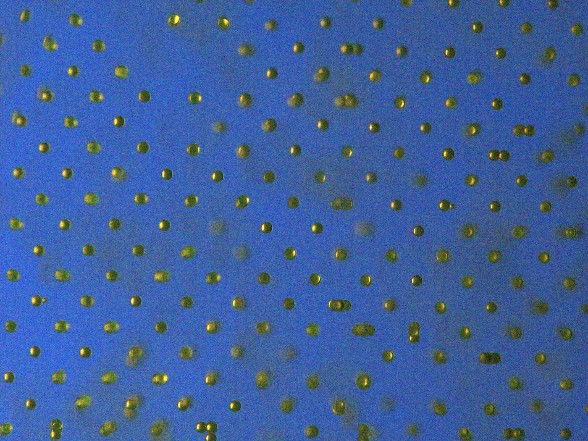

When particles are introduced into a standing wave field, acoustic radiation forces cause them to become trapped at regions of low acoustic pressure (or more correctly low acoustic potential energy). Here we seek to develop devices that harness these forces to carefully position macro-scale objects and micro-scale particles. There are applications for this technology in tissue engineering, where cells can be seeded in a pattern which aids the development of a specific type of tissue, for example, positioning cells in lines aids neuron development (Figure 2). There are also applications in the assembly of composite materials with structural reinforcement on nano- and micro- scales (i.e. so called hierarchical composites). A particularly exciting concept is to combine ultrasonic assembly with 3D printing. Here the ultrasonic field can allow particles to be arranged within the printed polymer, giving the printed material anisotropic properties.

Research in this area focuses on:

- Acoustic tweezers that trap and move individual particles which can be then manipulated under a microscope.

- Ultrasonic assembly of structured materials.

- Large-scale ultrasonic forces and Ultrahaptics.

Working in this area

Dr Asier Marzo – levitating atoms for humancomputer inter-action

Maddy Nichols (PhD) – ultrasonic assembly of structured gels

Agesinaldo Silva (PhD) – ultrasonic particle manipulation

Pradeep Bhaskar (PhD) - ultrasonic assembly of colloidal materials

Amanda Franklin (PhD) - microbeam manipulation

Contact