Researcher in Additive Manufacturing of Electrical Machines

Are you an electrical machine designer, computational or additive manufacturing engineer looking to apply your background to next generation electrical machine technologies in pursuit of Carbon Net Zero? We are seeking a motivated interdisciplinary researcher to join The Electrical Machine Works (UKRI Funded), University of Bristol, to develop high-performance metal 3D printed windings.

The successful candidate will work in a multi-institution, multi-disciplinary team across material science, process development, design for additive manufacture (DfAM), electromagnetic, thermal, mechanical, and computational design, software development, and experimental testing with opportunity for industrial collaboration and commercialisation. The appointee will already demonstrate detailed knowledge in several of these areas and be supported to grow their expertise into the role and lead their own activities within the project.

Context

Step improvement in electrical machine power density (kW/kg) is essential to the success of future More- and All-Electric transport initiatives and in achieving Carbon Net Zero targets. To this end, The Electrical Machine Works seeks to exploit the geometric freedom of metal Additive Manufacturing (AM) to simultaneously improve efficiency, thermal management, and electrical insulation temperature rating of electrical windings, Fig. 1, [1].

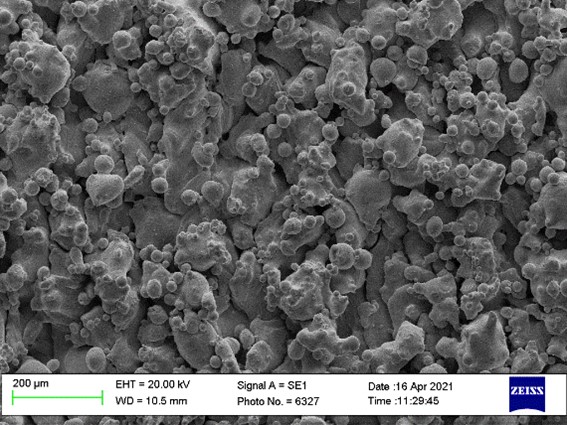

The design of such windings requires an understanding of 3D electromagnetic, thermal, and mechanical design along with design for additive manufacturing (DfAM) principles, CAD/CAM, software development, material characterisation, part and surface post-processing, Fig. 2, insulation coatings, [2-3], design of experiments and full-scale experimental validation.

As such, a motivated researcher with detailed background in some of these areas is sought to complement the existing multidisciplinary team in The Electrical Machine Works.

.gif) |

|

|

Fig. 1: CuCrZr shaped profile winding (prior to coating) |

Fig. 2: Scanning Electron Microscope (SEM) image of Cu winding surface |

[1] N. Simpson et al., “Additive manufacturing of shaped profile windings for minimal ac loss in electrical machines,” IEEE Transactions on Industry Applications, May 2020. doi: 10.1109/TIA.2020.2975763

[2] Y. Pang et al., “Ceramic / inorganic-organic nano-hybrid composites for thermally stable insulation of electrical wires. part i: Composition and synthetic parameters,” IEEE Transactions on Dielectrics and Electrical Insulation, vol. 27, no. 2, pp. 395–402, 2020.

[3] Y. Pang et al., “Ceramic / inorganic-organic nano-hybrid composites for thermally stable insulation of electrical wires. part ii: Properties of the composite insulated wires,” IEEE Transactions on Dielectrics and Electrical Insulation, vol. 27, no. 2, pp. 403–409, 2020.

What will I be doing?

The successful candidate will join The Electrical Machine Works under a multidisciplinary supervisory team who will provide support, training opportunities and project guidance. The researcher will be involved in the following activities (non-exhaustive):

- Learning relevant underpinning background material and application context

- Development of design tools and algorithms applicable to additive manufactured windings

- Bringing expertise to the research team and supporting others’ learning

- Electromagnetic, thermal, and mechanical analysis of electrical machines and sub-components

- In-depth literature reviews and collation of data

- Design of experiments, fabrication, and commissioning of test rigs for experimental validation of full-scale electrical machines and sub-assemblies

- Collaboration with industrial and internal and/or external academic partners

- Engagement and management of engineering suppliers

- Regular dissemination of findings via internal and external meetings and events

- Publication of findings at appropriate international conferences and in journal proceedings

- Mentoring of junior or cross-discipline researchers and PhD students

- Play an active role in the research group community for your own development and development of others.

Should I apply?

You should apply if you are a motivated, collaborative, research engineer having a detailed background (PhD level) in electrical machine design, computational design, or additive manufacturing with a desire to apply your knowledge to highly multi-disciplinary problems with real world impact potential in stepping toward Carbon Net Zero.

Closing date

January 9th 2022

Earliest start date

February 2022

Further Information

https://gow.epsrc.ukri.org/NGBOViewGrant.aspx?GrantRef=EP/T02125X/1

How to apply

Please apply here: https://www.bristol.ac.uk/jobs/find/details/?jobId=263754&jobTitle=Research%20Associate%2FSenior%20Research%20Associate%20in%20Additive%20Manufacturing%20of%20Electrical%20Machines

Direct research enquiries to Dr. Nick Simpson via nick.simpson@bristol.ac.uk