PhD Opportunities

Interested in the electric revolution, future of transport or Power Electronics? We're looking for enthusiastic and motivated students to join the EEMG.

Fully funded PhD scholarships for Chinese students to carry out research at the University of Bristol

Ultra-high-efficiency power electronics

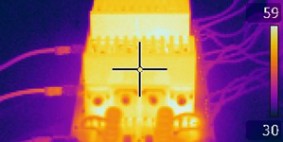

Thermal photograph of experimental ultra-high efficiency circuit under test

Super-Junction Transistor circuits

For cost reasons, kW level inverters deploy Insulated Gate Bipolar Transistors (IGBTs). However for high efficiency and high reliability applications, it is worth considering the use of Super-Junction MOSFETS.

Side-by-side comparisons with IGBTs show that Super-Junction MOSFET circuits allow up to 3-4 times the power throughput for the same circuit loss. Therefore, at the expense of some additional switching-aid circuitry and more expensive power devices, we obtain important system-level benefits including a much smaller circuit and the possibility of dispensing with forced cooling systems. The key to deploying Super-Junction MOSFETs is to effectively tackle the challenges presented by their inter-terminal capacitances and intrinsic diodes.

400V 1.5kW brushless DC machine drive: 99.2%

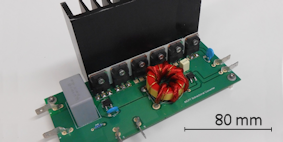

Brushless machine drive

The figure on the right shows a demonstration 1.5kW 400V 20kHz three-phase inverter for driving a brushless DC machine. This uses Super-Junction devices and, unusually for this power level, requires no forced cooling. 99.2% efficiency is conservatively estimated.

Thermal photograph

The thermal photograph shows the circuit running in the hard thermal steady-state. The maximum junction temperature rise is less than 35°C at 1.5kW.

One 5kW phase of an interleaved bidirectional DC to DC converter

DC to DC converter for electric vehicle ultra-capacitor systems

Compared to batteries, ultra-capacitor storage systems allow vehicles to regenerate more power during breaking and release more power during acceleration. In contrast to batteries, the voltage of supercapacitors changes significantly with stored energy.

This experimental interleaved bidirectional converter for vehicle ultra-capacitor storage is rated at 10kW (5kW per phase). Critical to the successful deployment of Super-Junction devices here is the toroidal inductor shown.

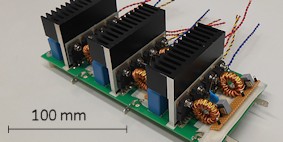

1kW 400V DC to DC converter and thermal photograph at full power

1kW DC to DC converter

As well as eliminating forced-cooling systems, the use of high-efficiency topologies can allow discrete heatsinks to be dispensed altogether with in some kW-level power converters.

This 1kW 400V DC to DC converter is entirely naturally cooled by means of copper planes on the printed circuit board. The measured efficiency is 99.5% in the steady state at full-load. The circuit has also been run in the steady state at 1.6kW and 450V.

50kHz buck converter with novel regenerative SiC BJT driver circuit: 99.15% efficiency excluding choke

SiC Bipolar Junction Transistor circuits

Other power device technologies we are investigating include SiC Bipolar Junction Transistor (BJT) circuits. SiC BJTs exhibit excellent performance, however, they need a steady-state base control current to hold them on (around 2% of the device current). We have developed a novel regenerative driver that supplies this control current directly from the device current, without requiring an inefficient base drive supply. The driver automatically supplies a current that is proportional to the device current. The efficiency of the 400V 2kW 50kHz converter shown is estimated at 99.15%.

720V 3kVA 3-level NPC converter

Multi-level topologies

As well as the common “two-level” converter topology, we have investigated the deployment of SJ devices in multi-level converters.

Multi-level converters' output voltages better approximate a sine wave, at the expense of increased control complexity. These tolopogies also allow the generation of output voltages that are higher than the voltage ratings of individual transistors.

600V 3kVA 3-level T-type converter

Shown are two recent examples (by N. McNeill and X. Yuan), which operate at efficiencies well above 99%, at full load, with no forced cooling.

The converters use switching-aid circuits to deactivate the inter-terminal capacitances and intrinsic diodes of the Super-Junction Transistors.

Research funding

This work has been funded by various grants, including:

- EPSRC Ultra-efficient grid-tie inverter technology

- EPSRC Power Electronics Centre

- Google Littlebox Challenge

- EPSRC Pulse Quietening, etc.

For technical enquiries, please contact Xibo Yuan.

How do you measure high efficiencies?

At high efficiencies, monitoring input and output power via the current and voltage waveforms is inaccurate. Up to a few 100s of watts we use a Keysight power analyser containing two 4-quadrant power modules.

At higher powers, two methods are used:

Thermal Superposition – First we apply a known loss to a component, and take a spot temperature reading. Then during operation of the converter, the temperature rise at this spot tells us the operating loss of this component.

Calorimetry – This is the most accurate method and is necessary for efficiencies of 99.5% and higher: The converter is operated in a highly insulated box. The air in the box is maintained at a specific temperature, by a cooling system. The power extracted by the cooling can be accurately measured and this tells us the losses of the converter.

This calorimeter was designed at Bristol and is controlled by means of an xPC controller implemented in Simulink.

Further reading

- N. McNeill, X. Yuan and P. Anthony, “High-Efficiency Multilevel Converter Technology for Electric Vehicle Applications using Super-Junction MOSFETs”, Proceedings, 5th IET Hybrid and Electric Vehicles Conference (HEVC 2014), London, UK, November 2014.

- N. McNeill, P. Anthony and N. Oswald, “Ultra-High Efficiency Machine Drive Inverter using Super-Junction MOSFETs”, Proceedings, 7th IET Power Electronics, Machines and Drives Conference (PEMD 2014), Manchester, UK, April 2014