Repairing contactless bank cards

Understanding integrated circuit failures is possible with micro-analysis sectioning.

Challenge

Using contactless cards for faster, easier electronic payments is becoming the norm.

This would not be possible without the extensive testing and simulation of prototype chips.

The contactless cards work using radio-frequency identification chips (RFID) that use their own source of power to access and transmit secure data stored within the chip. This kind of technology is also found in pets’ microchips, or in chip-tagged cargo on assembly lines.

Solution

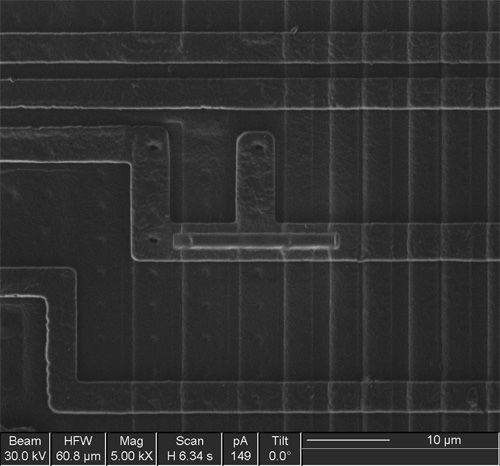

These circuits are smaller than a grain of rice, and repairs on a micrometre scale are impossible for factory equipment or electronics engineers.

They require the delicate and surface sensitive advantages of the FIB, SEM and TEM combined to unpick the layers, analyse any faults, and repair disconnected contact points, or diagnose problems with the metal within the integrated circuit.

An animation showing the step by step process of repairing the chip with the FIB and TEM using a platinum deposit

Courtesy of Peter Heard

Impact

While chips may be cheap to produce, costs can reach millions of pounds when distributed worldwide. And they need to be perfectly functional when sent to customers.

Any slight fault in the integrated circuit layers could cause a miscommunication between the transmitters and receivers, which can only be identified by observing nanometer thick sections and repairing them with the precise probe and observed via the electron microscope combined within the dual beam machine.