Identifying the composition of drill bits

Bristol helps the oil and gas industry to quantitatively understand and analyse complex composites and corrosion of important drilling materials.

Challenge

Drill bits undergo varying chemical conditions as they penetrate soil and bedrock, and may be exposed to aqueous conditions that could cause corrosion or failure more rapidly than if the drill is composed of more chemically stable and corrosion-resistant alloys.

Solution

To be absolutely certain of the drill bits’ chemical composition, micro-scale resolution is required both in the SEM images and in the EDX qualitative analyses, and in XRD quantitative compositional analyses.

By looking at the microstructures and checking for key elements in the alloys, their spatial distribution and chemical proportions can be produced and visualised clearly in maps showing the crystals or lattice structures and identifying what elements are there.

By carrying this out across several samples, the client can be confident that their product is the chemical composition that they think it is, and that it matches international standards.

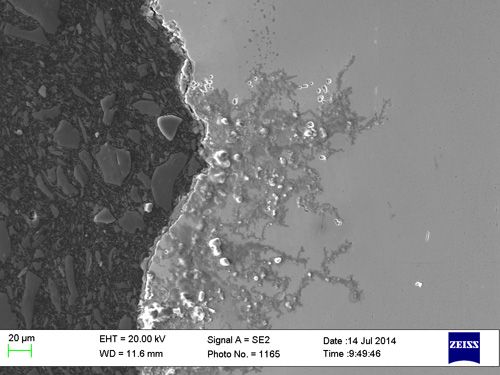

Corrosion products forming on steel

Courtesy of Adel El-Turki

The corrosion occurs at cracks and weaknesses and spreads outwards into the rest of the metal

Impact

A comprehensive statistical analysis of multiple samples can confirm the manufactured parts are up to international standard specifications.

The actual composition of drill bits and bearings is crucial both to those manufacturing them and in the energy industry where the composition can ultimately impact the lifetime of these parts, contributing to costs of drilling, and also impact the yield of the resource.