Workshop services

Across the three disciplines, we consult, design, manufacture, modify, repair & test

We are experienced in equipment design and manufacture techniques associated with a variety of modern technical specialty processes, for example:

- High and ultra-low vacuum

- Cryogenics

- Chemical synthesis and spectroscopy

- Laser and optical rigs

- AFM and electron microscopy

- X-Ray techniques

- Medical, veterinary and clinical research

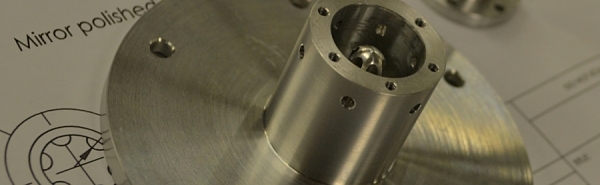

Mechanical Workshops

- Working in metals, plastics and wood

- Working on components for high temperatures, high pressures, ultra-low temperature, ultra-high vacuum, high environmental stress etc

- Advanced manufacturing: milling, turning, lasercutting, waterjet cutting and 3-axis CNC lathe

- Various welding techniques available: DC, MIG & TIG (Steel, Stainelss and Alloy etc.), spot (incl. micro spots eg foils), oxy-acetylene, laser, hard soldering/brazing and soft soldering

- Working from CAD drawings or from basic conceptualisation

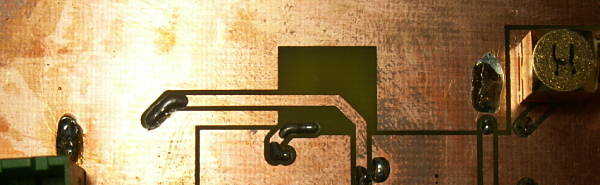

Electronics Workshop

- A design / prototype / manufacturing service for both analogue and digital electronic equipment.

- Fault finding and repair of ready built equipment/apparatus.

- Wide range of electrical / electronic test equipment, including an SMD re-work station. W

- Schematics, circuit operation simulation and PCB design, up to 16 layers primarily using the Cadence CAD package.

- Design of both hardware and firmware for the implementation of control and measurement systems. To this end we are familiar with the architecture and programming of the PIC microcontroller family.

- LabVIEWTM support.

- The workshop has ample prototyping bench space.

Glass Workshops

- Hot glass and pyrex work

- Repairs, modifications and novel apparatus manufacture

- Metal/Glass seals manufactured

- Abrasive waterjet cutting, precision glass diamond sawing and grinding

- Vacuum and encapsulation work

Head to the intranet to see some example work