Raman thermography improves chip lifetimes

Raman thermography measures the temperature of tiny semiconductor device structures, helping companies around the world improve the lifetimes of their products.

Electronic devices get hot during use and the hotter they get, the shorter their lifetime.

So semiconductor manufacturers are keen to know which parts of a device, and the circuits inside its chip get hot and why, because this will enable them to develop chips that perform better and last longer.

This is particularly important for devices made from silicon, gallium nitride and gallium arsenide because these devices have applications in space, radar, communication, and power conversion.

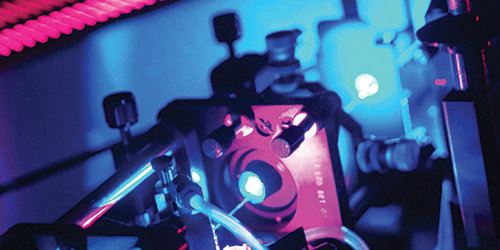

Developed by researchers from the School of Physics, Raman thermography is a technique for measuring the temperature of semiconductor structures just a few hundred nanometers in size. Today this technique is used by many of the major chip manufacturers to improve the performance, lifetime and reliability of their devices.

Developing Raman thermography

Critical device dimensions in this semiconductor technology range from the sub-micron to only a few micron. This makes measuring their temperature beyond the capability of conventional techniques such as infrared thermography. So in order to measure the temperature of features such as the active device channels in these chips, Professor Martin Kuball and colleagues from the School of Physics developed a new technique called Raman thermography.

“Semiconductor companies from around the world rely on us to accurately measure the temperature of their devices. This enables them to develop more robust, reliable, higher performing devices and circuits for high-end space, radar, communication and power conversion applications” explains Professor Kuball.

In 2002 Professor Kuball’s group demonstrated that Raman scattering spectroscopy can be applied to measure channel temperature in these and other semiconductor devices with sub-micron spatial resolution throughout the device structure.

The technique measures vibrations of atoms inside the device, making sure to separate out the temperature effects from the stress/strain effects that both influence the energy of these vibrations in the semiconductor devices.

“We needed to gain a detailed understanding of how temperature and stress/strain affect atomic vibrations in the semiconductor, and how this can be taken advantage of in a semiconductor device context,” says Professor Kuball.

“We used this knowledge to develop the technique to accurately quantify channel temperature in semiconductor devices, and also heat transfer across interfaces inside the semiconductor devices, including the impact of material imperfections such as dislocations.”

This also included the implementation of the ability to measure temperature transients in semiconductor devices with nanosecond time resolution, which is essential both for microwave and for power switching devices.

Testing for major semiconductor manufacturers

Since 2007 many of the world’s major semiconductor manufacturers have been sending their devices to Professor Kuball’s group for testing.

“Semiconductor companies from around the world rely on us to accurately measure the temperature of their devices,” says Professor Kuball. “This enables them to develop more robust, reliable, higher performing devices and circuits for high-end space, radar, communication and power conversion applications.”

The results from the Bristol group’s tests are used by the companies to optimise processing and device design.

When the group started working with companies, typical lifetimes of new devices developed were in the thousands of hours. But most commercial applications require at least a million hours and in some cases a billion hours are needed.

“Most of the companies we work with are now achieving these lifetimes for their devices because the information we give them enables them to validate the models they use to design their devices,” says Professor Kuball. “Without the information we are able to gather, they have no way of knowing if the predictions made by the models are accurate.”

This has enabled the companies to enter new markets, meet customer demands and expand their businesses.

The researchers are looking to licence the technology to equipment manufacturers and are also planning to develop a low-cost version of the Raman thermography system.

Related publications

Funders

Study Physics

Study Physics

Contribute to cutting edge research at the very frontier of scientific knowledge.