Chris, a Ph.D. student in the EPSRC Centre for Doctoral Training in Advanced Composites for Innovation and Science (ACCIS CDT), won the £150 prize for his paper ‘WrapToR composite truss structures: Improved process and structural efficiency’ (Composite Structures, Volume 230, December 2019, 111467).

The prize is awarded annually to the fourth year Ph.D student in the ACCIS CDT judged to have produced the best composite research paper applicable to the aerospace, oil and gas, renewables, or medical industries. Paper quality is informed by the number of independent citations and the impact factor of the journal.

The judging panel were particularly impressed with the novel applicability and elegance of manufacturing design displayed in Chris’ work.

With a face-to-face prize being prevented by the ongoing pandemic, earlier this month Chris presented his winning paper and current research to representatives from Victrex and the University of Bristol via videoconference.

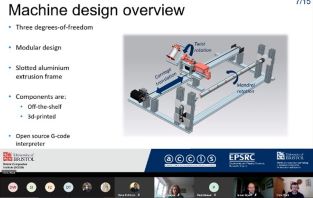

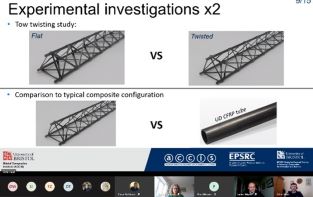

The presented work focused on developing the manufacturing process of a novel, extremely lightweight composite structure: the WrapToR Truss. First, the process was automated by designing and building a truss winding machine. Manufactured trusses were then experimentally compared to conventional composite structures where huge increases in structural performance were demonstrated. The work also showed how a simple modification to the process, tow twisting, could significantly improve truss performance.

Prize sponsor, Victrex plc, is an innovative world leader in delivering high performance engineering thermoplastic solutions based on aromatic polyketones, such as PEEK and other members of the PAEK family of high performing polymers. Thermoplastic composites are receiving increasing attention as matrices in the composites industry, particularly in the aerospace, automotive and oil and gas sector, due to their inherent toughness and greater potential for recycling at end of life.

Dr James Myers, Head of Research and Development for Aerospace and Composite Applications at Victrex, said: “The WrapToR process shows an encouraging approach for manufacturing light-weight high relative stiffness and strength structural components. Great to see a technology development that has such a large potential for commercial exploitation. It will be great to see this work with Thermoplastic materials in due course too.”

Chris said: “Thanks to Victrex and the judges for the award. I am very grateful for the prize, but also to the team who took time out of their days to hear about my research. It was great to meet some new faces. Such opportunities are few and far between in current times!”

More Bristol Composites Institute news.