Accelerating the development of composite wind turbine and aerospace components

Manufacturers benefit from advanced numerical simulations developed at the Bristol Composites Institute.

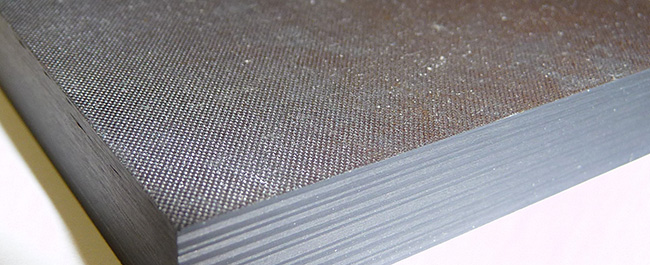

Composite materials such as carbon-fibre reinforced polymers are important for large aerospace and wind energy structures, providing structural strength and stiffness comparable to metallic alloys but at a lighter weight and with good corrosion and fatigue-resistant properties.

Building large-scale structures with components produced from two or more constituent materials is a challenge though, mainly because mechanisms, such as thermal expansion and cure shrinkage of resin, often lead to stresses and part distortions during manufacturing.

Thanks to research at Bristol Composites Institute, it is now possible for manufacturers to solve these problems so they can accelerate time to market, save costs in production and significantly reduce the risk of producing out-of-spec products.

Predicting defects

The main issue with mechanisms like thermal expansion and cure shrinkage, is that they usually act collectively throughout the manufacturing process, often leading to significant changes to the geometry of the original intended design.

This research focused on two key areas that resulted in the development of numerical tool sets for predicting manufacturing deformations.

The COMPAVS (Composite Processing Avoiding Variability and Stress) project provided a fundamental understanding of the mechanisms generating residual stresses and distortions, the different roles of cure shrinkage and thermal stresses and the importance of tool-part interaction. For the first time this made it possible to measure how stresses develop due to the action of these mechanisms during the cure process.

The DEFGEN (Defect Generation Mechanisms in Thick and Variable Thickness Composite Parts) project investigated the consolidation of uncured composite materials pre-impregnated with epoxy resin (pre-preg) and the impact of this on the formation of defects during composite manufacture. Bristol’s research team also developed new testing methods to accurately measure the compaction of uncured pre-preg at various temperatures, rates and length scales – making it possible to identify and characterise multiple flow mechanisms (such as shear and percolation) in material types in a way that had never been achieved before.

Benefits for industry and the planet

The research has led to significant economic and practical impacts that are being driven by LMAT Ltd - an SME that is using the research to provide consultancy services to composite component manufacturers and predict distortions for their clients.

LMAT has enabled VESTAS – one of the world's biggest wind turbine businesses – to increase production quality by reducing defect and scrap rate. As a result VESTAS has also been able to reduce the production costs of over 2,500 turbines made from composite materials. Globally, these turbines are now generating more than 8GW of power.

LMAT has also played a significant role in supporting GKN Aerospace in the design of the Airbus A350 XWB wing trialling edge spar tooling. The aircraft is Airbus' first to have both a carbon-fibre wing and fuselage.

Overall LMAT's work has supported the production of spars for 360 A350s and there are now 930 more on order – making it possible for airlines around the world to introduce lower weight aircraft that consume less fuel and help fulfil their mission to reduce carbon emissions.

Work with us

Work with us

Our Industrial Liaison Office helps you to develop research partnerships.

Quick facts

- Numerical algorithms make it possible to predict deformations during manufacturing.

- Work has supported production of over 2,000 wind turbines and 1,000 aircraft globally.

- Impact includes reduced production costs and benefits for climate change.